با افزایش تقاضا برای نظارت بر بارهای جاده ها و پل ها در مدیریت ترافیک مدرن، فناوری وزن در حرکت (WIM) به یک ابزار ضروری برای مدیریت ترافیک و حفاظت از زیرساخت تبدیل شده است. محصولات سنسور کوارتز Enviko با عملکرد عالی و قابلیت اطمینان خود به طور گسترده در سیستم های WIM استفاده شده اند.

اصول الگوریتم های کوارتز وزن در حرکت (WIM).

هسته سیستم وزن در حرکت کوارتز (WIM) اندازه گیری فشار وارد شده بر سطح جاده توسط وسایل نقلیه در زمان واقعی با استفاده از سنسورهای کوارتز نصب شده در جاده است. سنسورهای کوارتز از اثر پیزوالکتریک برای تبدیل سیگنال های فشار به سیگنال های الکتریکی استفاده می کنند. این سیگنال های الکتریکی تقویت، فیلتر و دیجیتالی می شوند و در نهایت برای محاسبه وزن وسیله نقلیه استفاده می شوند.

سنسورهای کوارتز Enviko که در سیستمهای WIM به کار میروند، دارای حساسیت بالا و ویژگیهای پاسخ فرکانس وسیع هستند، که آنها را قادر میسازد تا تغییرات فشار لحظهای را با عبور وسایل نقلیه از روی آنها به دقت ثبت کنند. علاوه بر این، سنسورهای کوارتز دارای ثبات دمایی عالی و عمر طولانی هستند و عملکرد پایدار را در محیطهای مختلف خشن حفظ میکنند.

مراحل الگوریتم وزن در حرکت (WIM).

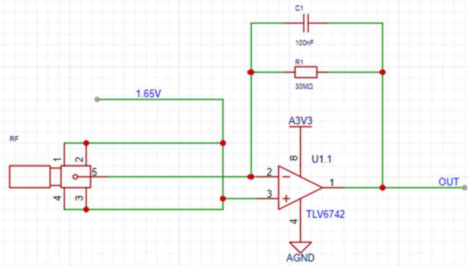

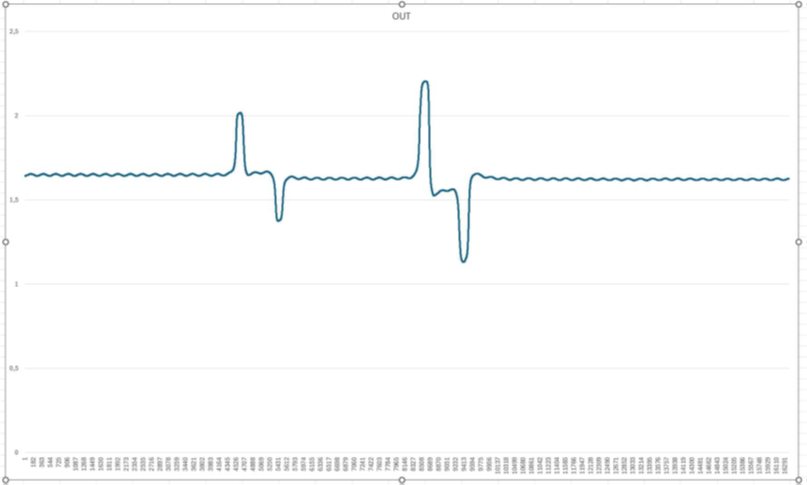

1.دریافت سیگنال: سیگنال های فشار اعمال شده توسط وسایل نقلیه عبوری را با استفاده از سنسورهای کوارتز گرفته و این سیگنال ها را به سیگنال های الکتریکی تبدیل کرده و به سیستم جمع آوری داده ها منتقل می کند.

2.تقویت سیگنال و فیلتر کردن: سیگنال های الکتریکی به دست آمده را تقویت و فیلتر کنید تا نویز و تداخل را حذف کنید و اطلاعات وزن مفید را حفظ کنید.

3.دیجیتال سازی داده ها: تبدیل سیگنال های آنالوگ به سیگنال های دیجیتال برای پردازش و تجزیه و تحلیل بعدی.

4.تصحیح پایه: تصحیح خط مبنا را بر روی سیگنال ها انجام دهید تا جبران بار صفر را حذف کنید و از دقت اندازه گیری اطمینان حاصل کنید.

5.پردازش یکپارچه سازی: سیگنال های تصحیح شده را در طول زمان ادغام کنید تا کل شارژ را محاسبه کنید که متناسب با وزن خودرو است.

6.کالیبراسیون: از فاکتورهای کالیبراسیون از پیش تعیین شده برای تبدیل کل شارژ به مقادیر وزن واقعی استفاده کنید.

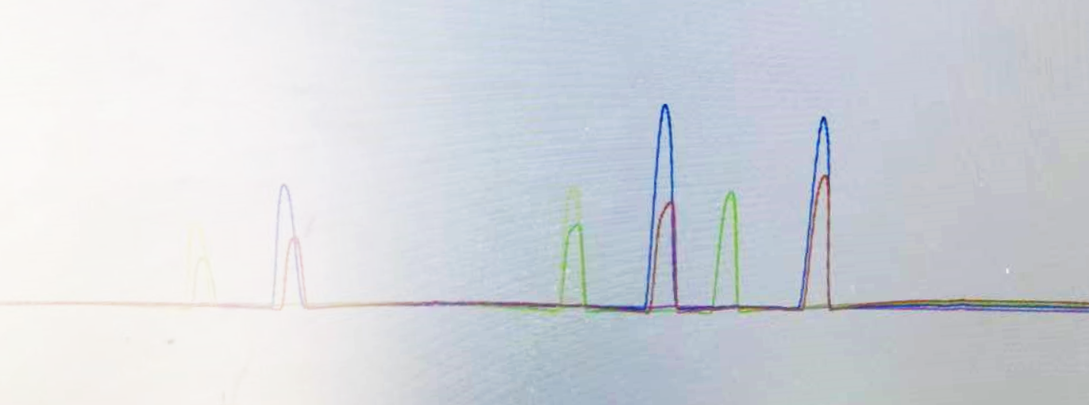

7.محاسبه وزن: اگر از چند سنسور استفاده می شود، وزن هر سنسور را جمع کنید تا وزن کل خودرو را بدست آورید.

رابطه بین الگوریتم ها و دقت

دقت سیستم Weigh-In-Motion (WIM) تا حد زیادی به الگوریتم های مورد استفاده بستگی دارد. سنسورهای کوارتز Enviko دقت اندازه گیری وزن را از طریق دریافت و پردازش سیگنال با دقت بالا تضمین می کنند. دقت و کارایی الگوریتم های پردازش داده ها به طور مستقیم بر نتایج وزن گیری نهایی تأثیر می گذارد. پردازش سیگنال پیشرفته و الگوریتم های تجزیه و تحلیل داده ها می تواند به طور موثری دقت توزین را بهبود بخشد و خطاهای اندازه گیری را کاهش دهد.

به طور خاص، دقت دریافت سیگنال، اثربخشی فیلتر کردن نویز، و دقت فرآیندهای یکپارچه سازی و کالیبراسیون، عوامل کلیدی موثر بر دقت توزین هستند. سنسورهای کوارتز Enviko در این زمینه ها برتری دارند و از دقت و قابلیت اطمینان بالای سیستم های WIM از طریق الگوریتم های پیشرفته و سخت افزار با کیفیت بالا اطمینان حاصل می کنند.

رابطه بین نصب و دقت

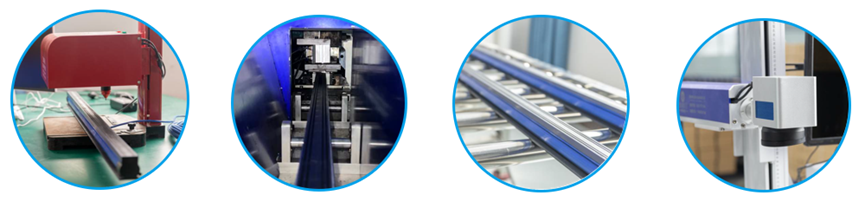

موقعیت و روش نصب سنسورهای کوارتز به طور قابل توجهی بر دقت اندازه گیری سیستم WIM تأثیر می گذارد. برای اطمینان از ثبت دقیق تغییرات فشار حداکثر، سنسورها باید در موقعیتهای کلیدی در مسیر خودرو نصب شوند. هنگام نصب، اطمینان از تماس نزدیک بین سنسورها و سطح جاده برای جلوگیری از خطاهای اندازه گیری به دلیل نصب نادرست ضروری است.

علاوه بر این، عوامل محیطی مانند دما، رطوبت و صافی زمین نیز میتوانند بر عملکرد و دقت اندازهگیری سنسور تأثیر بگذارند. اگرچه سنسورهای کوارتز انویکو از پایداری دمایی عالی برخوردار هستند، اما اقدامات جبرانی مناسب همچنان در شرایط دمایی شدید برای اطمینان از نتایج اندازهگیری دقیق مورد نیاز است.

کالیبراسیون و نگهداری منظم نیز برای اطمینان از عملکرد پایدار درازمدت سنسورها ضروری است. از طریق نصب و نگهداری حرفه ای، عملکرد سنسورهای کوارتز Enviko را می توان به حداکثر رساند و داده های وزن دینامیکی دقیق و قابل اعتماد (WIM) را ارائه داد.

نتیجه گیری

استفاده از سنسورهای کوارتز Enviko در سیستم های توزین پویا (WIM) راه حل های کارآمد و قابل اعتمادی را برای مدیریت ترافیک و حفاظت از زیرساخت ارائه می دهد. سیستمهای توزین پویا کوارتز (WIM) از طریق دریافت سیگنال دقیق، پردازش الگوریتم پیشرفته، و نصب و نگهداری حرفهای، میتوانند به نظارت و مدیریت بیدرنگ وزن خودرو دست یابند، به طور موثری سایش و پارگی جاده و پل را کاهش دهند و کارایی مدیریت ترافیک را بهبود بخشند. با پیشرفتهای مداوم فناوری، حسگرهای کوارتز Enviko نقش مهمی را در سیستمهای WIM ایفا میکنند و پایهای محکم برای توسعه حملونقل هوشمند فراهم میکنند.

Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

دفتر چنگدو: پلاک 2004، واحد 1، ساختمان 2، پلاک 158، خیابان تیانفو 4، منطقه فناوری پیشرفته، چنگدو

دفتر هنگ کنگ: 8F، ساختمان Cheung Wang، خیابان San Wui 251، هنگ کنگ

زمان ارسال: اوت-07-2024